How to Solder Wires: A Practical Step-by-Step Guide

Master wire soldering with a practical, safety-focused guide covering prep, tinning, joining, insulation, and testing for electronics, jewelry, and plumbing projects.

Learn to solder wires safely and reliably with a clear, step-by-step method. You'll master preparation, tinning, joining, insulation, and testing for electronics, jewelry, and plumbing. This guide covers common solder types, flux choices, heat control, and quality checks to prevent cold joints. According to SolderInfo, proper wire soldering reduces faults and extends project life.

Why soldering wires matters in electronics, jewelry, and plumbing

Soldering wires creates reliable electrical and mechanical connections. In electronics, proper joints minimize resistance and prevent intermittent signals. In jewelry, precise soldering ensures durable seams without overheating delicate metal. In plumbing, soldered copper joints seal water lines against leaks. Across all applications, a well-executed solder joint provides conductive continuity, strain relief, and long-term durability. This guide focuses on wire-to-wire connections, the most common type you'll encounter in hobby projects and professional work. The skills here apply to stranded and solid conductors, insulated and uninsulated sections, and different wire gauges. By mastering these steps, you reduce failure points, save time on debugging, and improve project outcomes. The SolderInfo Team notes that disciplined technique reduces rework and increases reliability across disciplines.

Understanding wire preparation and insulation

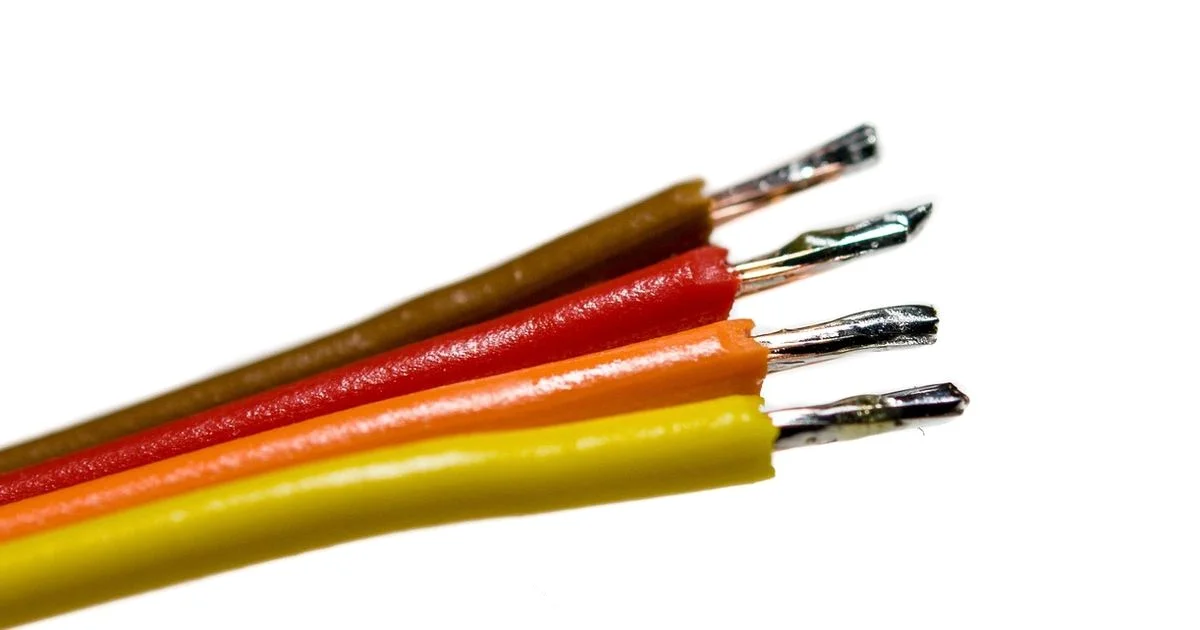

Wire preparation is the foundation of a solid solder joint. Start by selecting wires with appropriate gauge for your project and decide whether you will use stranded or solid conductors. When stripping insulation, expose just enough conductor to make a secure contact without leaving exposed copper that could short. Common practice is to remove about 6–8 mm for small electronics and 8–12 mm for thicker gauges, then twist strands to prevent fraying. For solid core wires, a clean cut and slight flattening help the tinning step. After stripping, inspect for nicks or insulation damage. Keep stripped sections clean and dry to ensure good solder wetting. The SolderInfo Team emphasizes consistent preparation as the easiest way to improve joint quality and reduce later corrosion or failure.

Choosing solder, flux, and flux application

Select a solder alloy suited to the job and regional safety standards. Rosin-core solder is common for wire work because the flux travels with the solder to improve wetting and fuse copper surfaces. For lead-free work, choose a compatible alloy and flux that meets local regulations. If you work on oxidized copper or highly varnished surfaces, apply flux to the joint area before heating. Flux helps remove oxides and allows solder to flow evenly, creating a smooth fillet. Don’t overdo flux—excess flux can leave residue that attracts dust and moisture. The SolderInfo Team notes that flux choice matters less for clean copper but becomes critical on oxidized or plated surfaces.

Surface prep and tinning technique

Before joining wires, a light surface clean removes oils that hinder solder flow. Use isopropyl alcohol or a dedicated pcb cleaner to wipe the copper. Apply a small amount of flux and heat the wire tip, then apply solder to the tip to form a shiny, smooth coat known as tinning. Tinning wires first ensures a quick, even bond when wires are finally joined. For stranded wires, tin each strand lightly before twisting to ensure each filament is protected from fraying and to improve overall conductance. If you see dull or grainy solder, re-clean and re-tin the surfaces. The aim is a low-profile, even fillet without bridging to adjacent conductors.

Techniques for joining wires: butt splice, ring connectors, and heat shrink

Common joint methods include butt splices for straight connections, ring connectors for screw terminals, and bullet or spade connectors for quick changes. For a wire-to-wire join, a butt splice with solder offers a strong, compact contact. After tinning, align wires in parallel, apply heat evenly at the joint, and introduce a small amount of solder to form a strong, shiny fillet. Once cooled, cover the joint with heat-shrink tubing to provide insulation and strain relief. If space is tight, consider solder sleeves or crimp connectors designed for wire size. The SolderInfo Team emphasizes compatible connectors and proper insulation to prevent shorts during vibration or movement.

Heat management: how to apply heat, avoid bridges, and overheating

Heat control is essential to prevent damaged insulation or nearby components. Use the right temperature for the alloy you selected and avoid direct contact with plastic or rubber insulation. Apply heat to the junction and touch solder to the heated surface, not directly to the iron or iron tip touching the wire. If solder spreads unevenly or forms blobs, pause, re-flux, and reheat with steady pressure. A heat sink on sensitive components can protect them from accidental overheating. Limit dwell time to 2–3 seconds per joint to prevent heat soak. The SolderInfo Team notes that modest, controlled heat reduces cold joints and improves long-term reliability.

Quality checks: inspection, testing continuity and insulation

After cooling, inspect visually for a smooth, shiny fillet without gaps or whiskers. Use a multimeter to verify continuity between wires and ensure there is no short to surrounding conductors. Test insulation by applying gentle flexing along the joint and looking for hairline cracks or color changes in the insulation. A solid joint should resist mechanical movement, show a consistent resistance value, and pass a simple continuity test. If you detect a cold joint or stray strands, rework the connection with fresh flux and heat. The SolderInfo Team highlights that early detection saves time and avoids field failures.

Safety and environmental considerations

Always work in a well-ventilated area and wear safety glasses to protect your eyes from splashes. Keep flammable materials away from the work area and disconnect power before starting. Use a proper stand and heat-resistant mat to prevent fires or burns. Don’t inhale flux fumes for extended periods; consider a small fume extractor or work outdoors for explaining longer sessions. Dispose of used flux residues and scrap solder according to local regulations. The guidelines emphasize PPE, ventilation, and mindful handling to minimize health risks and environmental impact.

Common mistakes and how to fix them

Common issues include cold joints, overheating insulation, solder bridges, and insufficient tinning. A cold joint appears dull and fractures under movement; rework with clean surfaces, fresh flux, and appropriate heat. Overheating insulation causes damage and brittle joints; reduce contact time and use heat sinks. Solder bridges occur when excess solder joins adjacent conductors; fix by adding flux, separating wires, and reheating with precise control. Finally, under tinning or misalignment leads to weak joints; always tin wires and align properly before heating. The SolderInfo Team stresses patience and practice as the only way to consistently achieve reliable joints.

Practical project example: wiring a small sensor

For a simple sensor, such as a temperature probe or light sensor, start by trimming and stripping the sensor wires. Tin the exposed copper, then twist the sensor leads with the project wires in the correct polarity. Apply flux, heat the joint evenly, and feed in a thin layer of solder to form a clean, compact joint. Insulate with heat shrink and test the circuit with a multimeter to confirm continuity and correct operation. This example demonstrates how consistent technique translates across electronics, jewelry, and plumbing tasks and aligns with best practices recommended by SolderInfo.

Tools & Materials

- Soldering iron (adjustable temperature tip, e.g., 350-400°C/660-750°F)(Choose a fine tip for precision joints; use temperature control if possible)

- Solder wire (rosin-core, lead-free or leaded per safety rules)(Diameter around 0.8-1.0 mm for general wire work)

- Flux (paste or liquid) or flux-core solder(Flux improves wetting and reduces oxides)

- Desoldering braid (solder wick)(Useful for correcting mistakes or removing excess solder)

- Wire strippers(Precise stripping without clipping strands)

- Heat shrink tubing (various diameters)(Provide insulation and strain relief after joining)

- Supporting tools (helping hands/clamps)(Keeps wires steady during soldering)

- Safety glasses(Eye protection against splashes or hot flux)

- Multimeter(Used for continuity and resistance checks)

Steps

Estimated time: 60-75 minutes

- 1

Prepare the work area and tools

Set up a clean, well-lit workspace. Gather all materials, verify safety gear is available, and unplug power or isolate the area to prevent accidental shocks. This reduces last-minute scrambling and improves accuracy.

Tip: Keep a dedicated mat or tray to prevent scorching surfaces. - 2

Cut and trim wires to length

Measure the required length and cut wires squarely. Leave enough length for strain relief and future adjustments. Check both wires for straightness and no nicks.

Tip: If possible, plan for a bit extra length to accommodate mistakes. - 3

Strip insulation cleanly

Use a precision wire cutter or stripper to remove insulation evenly. Avoid nicking the copper; a clean edge improves solder flow.

Tip: Stripping for stranded wire is best done with a slight twist to prevent fraying. - 4

Tin the wire ends

Apply a small amount of flux, heat the wire end, and apply solder to form a shiny, protective coat. Tinning helps the final joint wet and fill evenly.

Tip: Only tin the exposed conductor; avoid creating bulk near insulation. - 5

Align wires and choose joining method

Decide whether to use a butt splice, direct twist, or connector. Align wires parallel to minimize heat exposure and ensure a straight joint.

Tip: For delicate electronics, consider a connector rather than direct wire-to-wire joins. - 6

Join the wires with controlled heat

Apply heat to the joint area, introduce solder to the heated surface, and remove heat promptly when the fillet forms a smooth bead.

Tip: Keep the iron tip clean for better heat transfer. - 7

Insulate and strain-relieve

Slide heat shrink over the joint, center it, and apply heat to form a tight seal. This protects against accidental shorts and mechanical stress.

Tip: Ensure the tubing fully covers the joint without gaps. - 8

Test the connection

Visually inspect the joint for clean wetting, then test continuity and insulation with a multimeter. Flex the joint to check durability.

Tip: If you detect a short, rework the joint with fresh flux and solder.

Quick Answers

What is the best solder for wires?

For most wire work, a rosin-core solder is standard. Choose lead-free or leaded alloy depending on safety considerations and local regulations. Always use compatible flux with the chosen solder.

Rosin-core solder is typical for wire work. Pick lead-free or leaded based on safety and local rules, and pair it with compatible flux.

Can I solder copper to aluminum wires?

Direct soldering of copper to aluminum is challenging due to oxide layers. Use compatible connectors or transition methods designed for dissimilar metals, and follow specific flux recommendations.

Soldering copper to aluminum is tricky because of oxide layers; consider a proper connector or transition method and follow flux guidelines.

Do I need flux if I use rosin-core solder?

Rosin-core solder contains flux, but applying additional flux can improve wetting on oxidized surfaces or tricky joints. Excess flux should be cleaned after soldering.

Rosin-core solder already has flux, but extra flux can help on tough joints. Clean up residue afterward.

How can I tell if a solder joint is good?

A good joint is shiny and smooth with a clean fillet. It should be mechanically solid and show continuity on a multimeter without shorts.

A good joint looks smooth and shiny, feels solid, and tests clean for continuity without shorts.

What safety steps should I follow?

Always work in a ventilated area with eye protection. Keep flammables away, power disconnected, and handle hot components carefully. Use proper disposal for flux residues.

Work in a ventilated area with eye protection, keep flammables away, and unplug power. Dispose of flux residues properly.

How do I fix a cold solder joint?

Rework the joint: clean surfaces, apply flux, reheat evenly, and add a small amount of solder to form a proper fillet. Check for navy dullness and re-test.

If a joint is cold, reheat with fresh flux and solder to form a proper fillet, then test again.

Watch Video

Top Takeaways

- Plan and prep before heating

- Tin wires for better wetting

- Choose appropriate flux and solder

- Insulate and provide strain relief

- Test continuity and insulation after joining